Toyota Gigacasting Prototype Cuts Production from Hours to Minutes

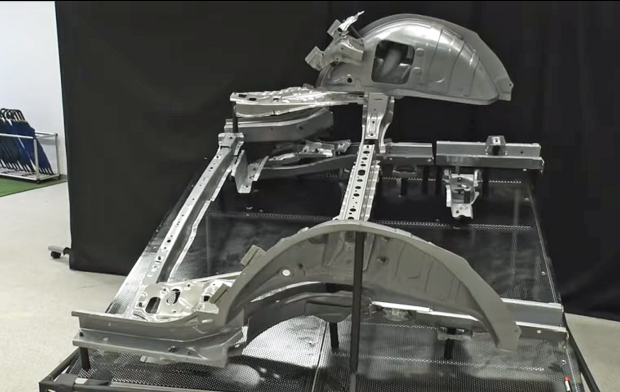

As reported by Asia.nikkei.com, Toyota Motor has shown off a prototype of its new gigacasting equipment that can make a third of a car body in about three minutes, a development that will be key to its plans to ramp up electric-vehicle production profitably in the coming years. The machine at the Japanese automaker's Myochi plant released a plume of white smoke as it ran during a recent demonstration for journalists. Molten aluminum poured in was rapidly cooled from 700 C to 250 C, solidifying into a single die-cast piece making up the entire rear third of the vehicle chassis. This is normally built from 86 parts in a 33-step process that takes hours. Toyota aims to exploit such advances to halve production processes, plant investment and manufacturing preparation lead time, all to aid in its quest to sell 3.5 million electric vehicles a year by 2030. If this technology takes hold, we will likely see its use in the fabrication of unmanned vehicles in multiple submarkets from tractors to ROVs. Other implications include the replacement of still more jobs by automation. Watch a video, here. Details on Toyota’s gigacasting at Asia.nikkei.com.